Cressbrook Dam has provided the Australian town of Toowoomba with safe drinking water since 1983. To protect this popular recreational destination in the long-term, a smart approach to safety was needed.

For over three decades the Toowoomba Regional Council has worked with digital, engineering, environmental design and construction professional services network, GHD, to ensure an ongoing, sustainable community water asset.

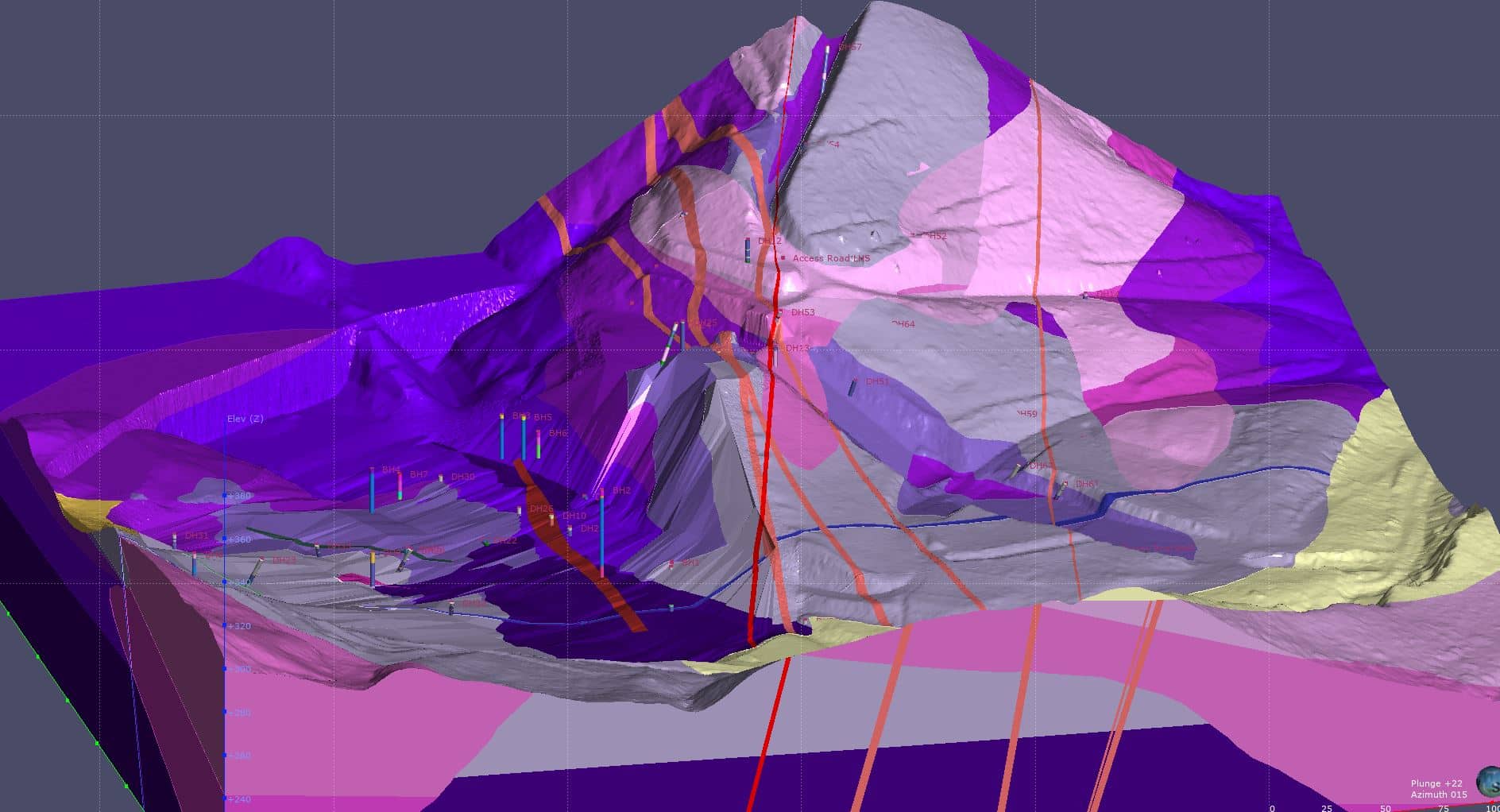

As part of these asset safety and management assessments and to facilitate the future use of historical information GHD developed a digital replica of Cressbrook Dam. This required an interdisciplinary approach, unifying geological investigations, hydraulic modelling, and other complex engineering elements.

By integrating Seequent and Bentley’s advanced software solutions, the team were able to consolidate all of their siloed data into a single source of truth.

“The innovative application of Bentley and Seequent’s 3D modelling and analysis software has enabled us to efficiently and effectively capture, collate, and assess the engineering geology of Cressbrook Dam,” said Christopher Bennett, Senior Technical Director – Engineering Geology, at GHD.

“Our geological team, including 3D Modeller, Graham Irvine and Photogrammetry SME David Field, converted years of historical dam data into a valuable digital asset and extending the value we can deliver for our client,” said Bennett.

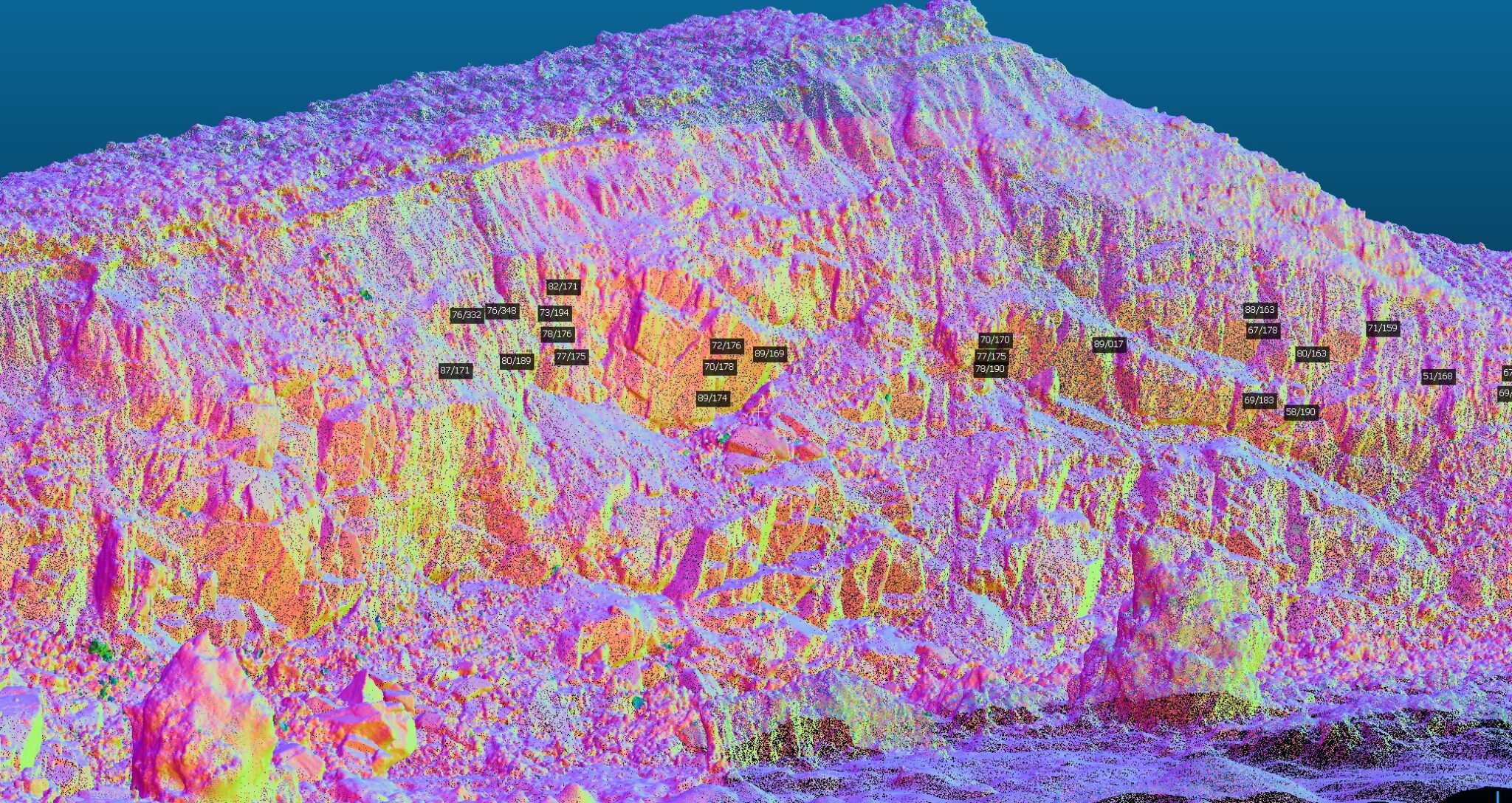

Photogrammetry model compiled from drone flights at the site, following initial geological mapping was imported directly into the 3D geological model (Credit: Graham Irvine)

30+ years

GHD’s geological team converted 3 decades of historical dam data into a valuable digital asset.

1983

Built in 1983, Australia’s Cressbrook Dam, is both a water supply and recreational attraction.

80,000 AUD

Creating a 3D model from drone imagery reduced site visits to a single trip, saving 80,000 AUD.

Linking past data with present conditions

Since GHD has a long history of working with Cressbrook Dam, they already had access to significant historic information to help with the geological data needed for the upgrade. This data included detailed design and construction files in both digital and paper formats, and historical geological mapping, borehole, and seismic information.

Combined, the data would enable the team to create a digital replica of the dam foundations, complete with geological, geotechnical, and engineering design information. But to better understand the underground, GHD had to find a way to link the past data with present conditions.

“Unfortunately, it was challenging to verify the historical detail buried beneath the dam structure. Overcoming this issue required data analysis using different techniques to provide a valid connection between the historical information and the current geological conditions,” said Christopher.

Additionally, parts of the dam with vertical batters or steep rocky surfaces made traditional approaches to collecting geological information treacherous. GHD needed a safer, more efficient method for gathering geological conditions and merging it with historical data.

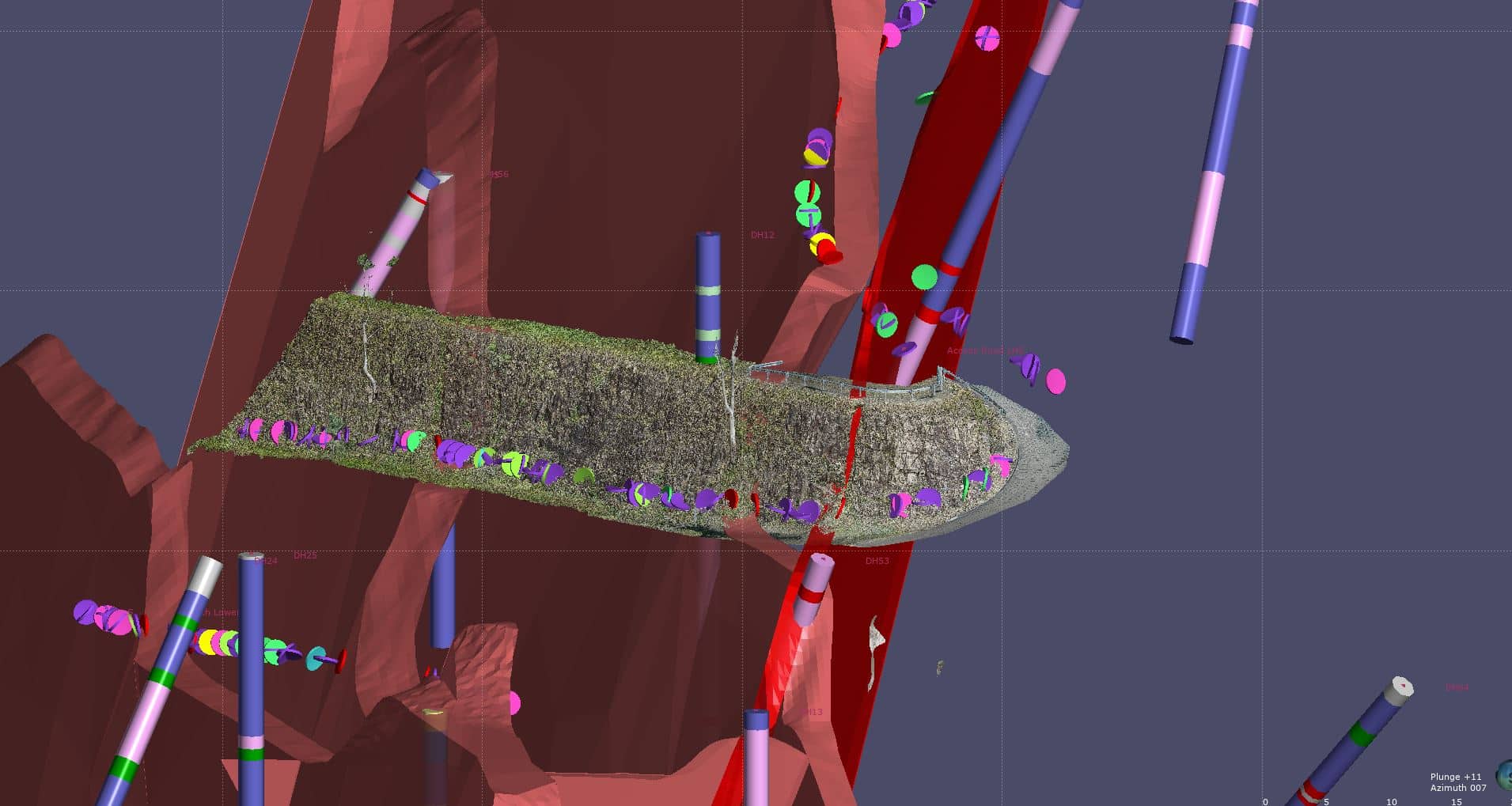

Combined image of photogrammetry, Leapfrog geological model, traditional geological mapping data and digitally analysed geological mapping information. (Credit: Graham Irvine)

Combining applications for a robust solution

Though GHD had long used individual software solutions from Bentley and Seequent, the team realised that combining the solutions could help them to assess current and past geological conditions more efficiently.

First, they established a single source of truth with Seequent Central, allowing the entire team (including those in New Zealand who were restricted by remote working) to contribute to the project.

Next, they captured images with drones and processed them in Bentley’s ContextCapture to obtain high-quality visual information about the dam and its rock outcrops, through a workflow method developed internally by David Field. With this data, GHD created a 3D reality model of the facility and its surrounding environment, enabling team members to visit the dam virtually, from their offices.

“Combining Seequent and Bentley’s suite of software allowed us to re-create the geological model as it would have been in 1983 augmented in 3D,” Graham Irvine said.

GHD then used Seequent’s Leapfrog Works to assess the ground conditions, gaining a complete understanding of the underground. The team incorporated the geological data into the reality model, providing an easy-to-understand visual representation of the state of the dam.

By overlaying historic geological maps onto the model, the team could compare past and present conditions – even the conditions from before the dam was constructed. And lastly, GHD incorporated historic borehole information into the Leapfrog model.

“This digital asset will be retained by the client and will be available to them for any future assessments of the dam, particularly for dam safety reviews that occur every five, 10, and 20 years,” said Christopher.

Point cloud image from aerial survey using drones and manipulated using Cloud Compare to provide rock defect assessment (Credit: Graham Irvine).

One model, many uses

Replacing a traditional dam assessment with an accurate 3D model created from drone imagery reduced visits to the site to a single trip, saving AUD 80,000, or 50% of the engineering geology fee, and keeping geologists safe.

The digital workflow also doubled the amount of information available and eliminated the risk of missing data. Being able to contribute to the project remotely via a connected data environment enabled work to proceed efficiently while continuing to enforce quality assurance and maintain project continuity.

The digital replica of the dam provides intuitive visualisation and data interpretation for all stakeholders, improving communication and decision-making throughout the phases of managing the dam. The team also used the model to create videos providing additional intuitive perspectives for the stakeholders of the dam.

Related case studies

How hidden ground risk is sinking the world’s largest projects

3D digital model deployed to evaluate underground route

Solving complex geotechnical design challenges for the longest Dam in South-East Asia.

GHD has already revised the digital model with new data as the assessment phases of managing the dam asset progress, and the model will be used into the future.

Having the digital model as a base for all decisions prevents rework and enhances consistency, helping to meet the goals of the upgrade and ensuring the dam and lake will remain a reliable, productive, and attractive asset for the region.

This GHD case study was submitted and presented at Bentleys prestigious 2022 YII Going Digital Awards in Infrastructure in London.

Updated geological model following incorporation of site information from the initial model which was built using historical information. (Credit: Graham Irvine).