3D modelling the complex geology to design the largest underground LPG storage facility in India, is challenging. But when it’s constructed beneath an existing, operating facility – the challenges become next level.

To better understand the underground the team at Engineers India Ltd (EIL) used Seequent’s Leapfrog Works to create highly visual 3D subsurface models, GeoStudio for insights into seepage analysis and, Seequent Central to enable easy collaboration and communication across stakeholders.

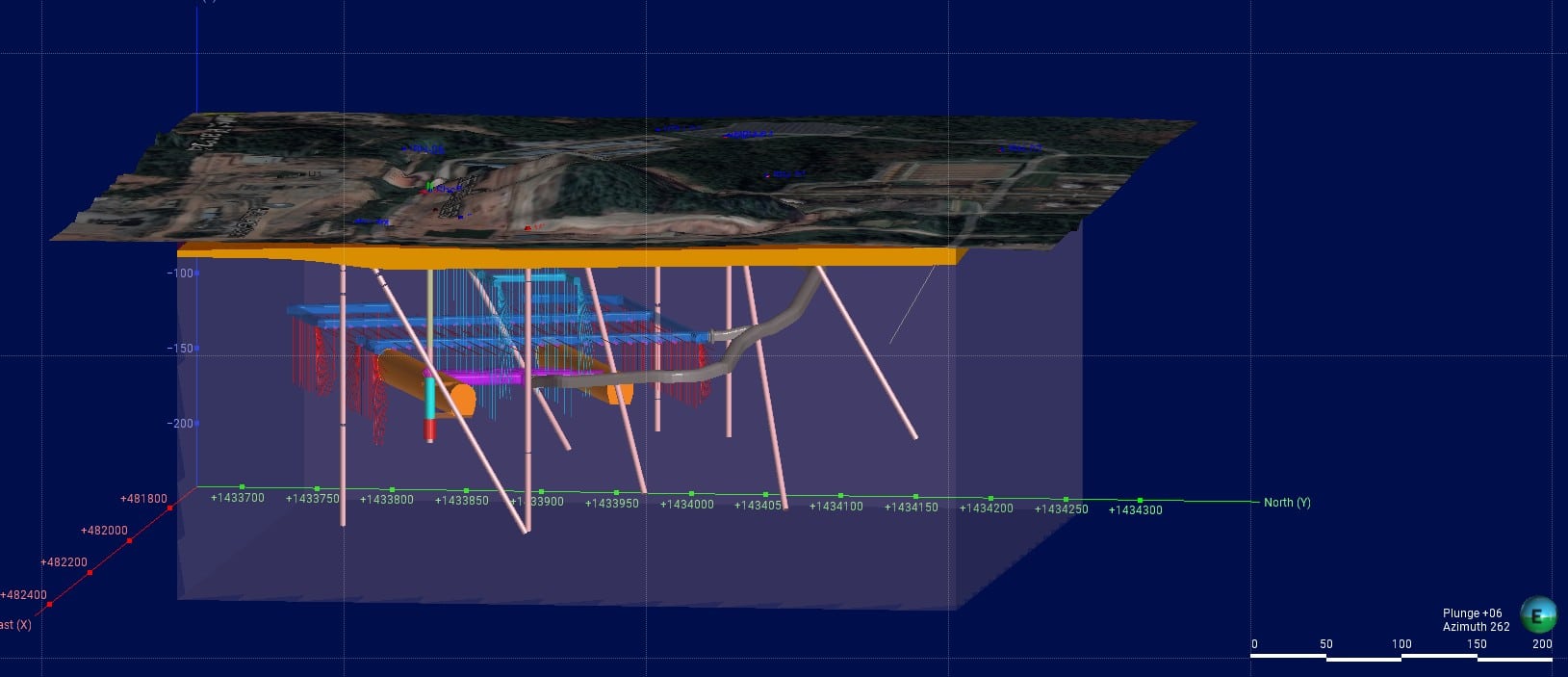

Google Earth image of project area

A complex underground storage facility

Constructed deep underground, rock caverns are considered a cost-effective and safe way to store hydrocarbons. Compared to aboveground storage, they require less land, minimise evaporation loss, have a longer lifespan and are more environmentally friendly.

Facilitating the creation of underground rock cavern storage also plays a vital role in reinforcing India’s energy security and complying with the IEA’s 90-day reserve requirement for strategic and commercial LPG supply.

But – like any major underground infrastructure project – it has proved very geotechnically complex for the engineers and designers involved.

“We are working on a challenging LPG storage project on India’s West Coast that involves constructing an underground unlined storage facility beneath an existing import facility and dispatch station,” says Saikat Pal, Senior Geologist and Deputy General Manager at Engineers India Limited (EIL).

Headquartered in New Delhi, EIL is an engineering and technology consultancy that provides services for major hydrocarbon, mining, infrastructure and power projects. Pal coordinates multiple project stakeholders including rock engineers, geologists, hydrogeologists and backup consultants.

“During our underground site investigations, our top priority and number one challenge has been to avoid disruptions and ensure the safety of the operational facility above. And, from a subsurface perspective, we’ve had to face many complex geological challenges, such as igneous intrusions and fractured, highly permeable rock,” says Pal.

100m

EIL delivered detailed design for the largest LPG storage facility in India, 100 metres underground.

20m x 30m

Excavated rock caverns are usually 20 metres wide, 30 metres high, and 300-1000 metres long.

130

We have imported 130 observations into our 3D cavern design

Crucial rock fracture insight to optimise fuel storage

Typically, an excavated rock cavern is 20 metres wide, 30 metres high, from 300 to 1000 metres long (depending on storage capacity) and accessed via vertical shafts or inclined drifts. The geology is often intricate, requiring extensive subsurface investigation to minimise surprises and de-risk construction.

“Our goal was to determine the geological, hydrogeological and geotechnical site conditions to ensure the project’s design, safety and cost-effectiveness,” says Pal.

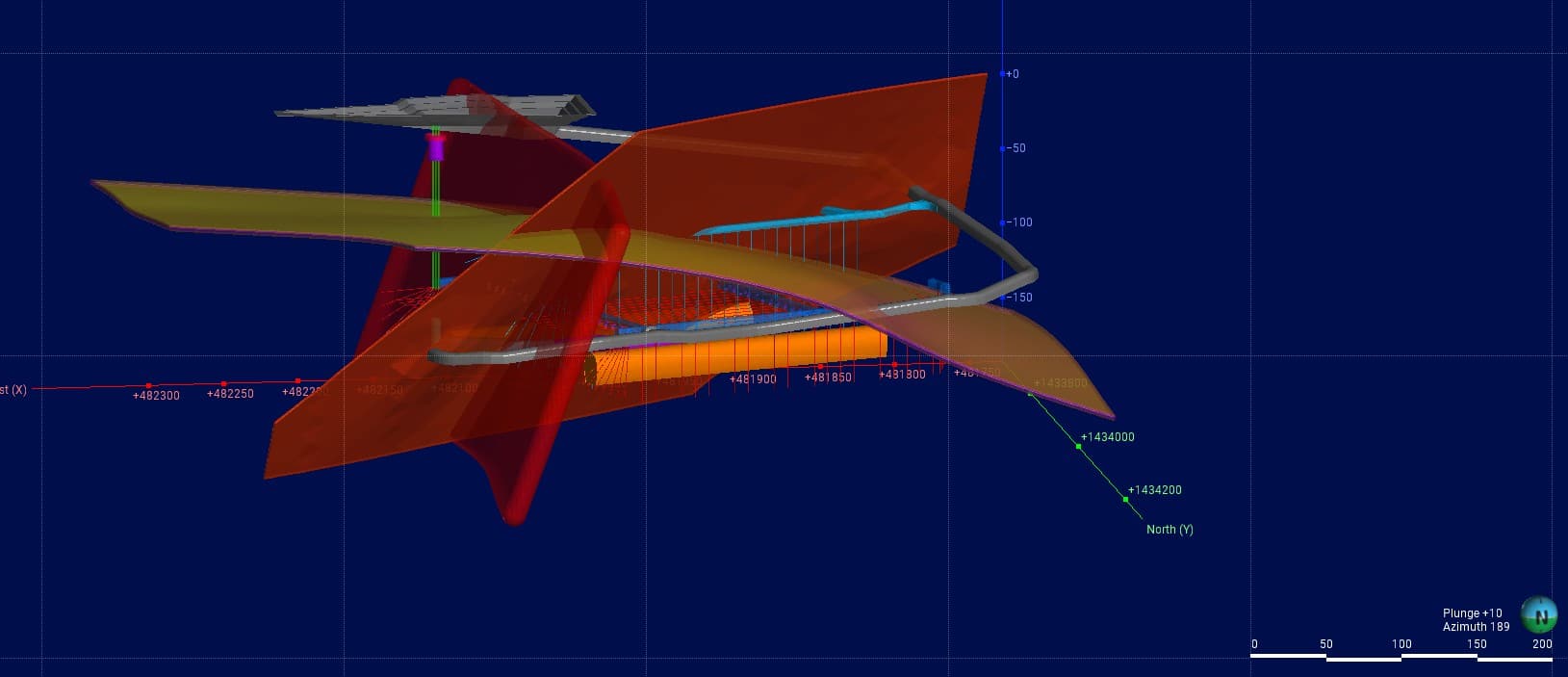

Around 100 metres below the surface and beneath the water table, the caverns can experience in-situ bedrock deformation, often resulting in fractures that enable high fluid flow. Understanding these fractures is crucial for ensuring the stability of the rock cavern and optimising fuel storage (so that hydrocarbons are not lost along these highly permeable zones).

“Using Seequent’s Leapfrog Works 3D geological modelling to accurately predict and understand the geology and structure of the bedrock, has been a game-changer,” says Pal.

Leapfrog Works integrates and visualises complex subsurface data to enable informed decision-making across civil engineering and environmental projects.

“Prior to using Leapfrog Works, we had to build our 3D models from 2D sections which was time-consuming and frustrating. Now, we simply integrate all borehole and geotechnical data to create an implicit 3D model and can take slices in any direction to easily and accurately analyse the geology,” says Pal.

Underground cavern below surface facility (Image: EIL)

Connected digital workflows to understand the underground

“What makes Leapfrog Works so powerful is that from the beginning we have been able to develop a deep understanding of the geological challenges and ground conditions to help de-risk construction. If any adverse features appear we can either avoid that zone or change the orientation of the structures,” says Nishant Kumar Mishra, Manager and Geologist at EIL.

Mishra works with the guidance of Pal and Seequent experts to 3D model the geological and hydrogeological aspects of the site’s underground tunnels in Leapfrog Works.

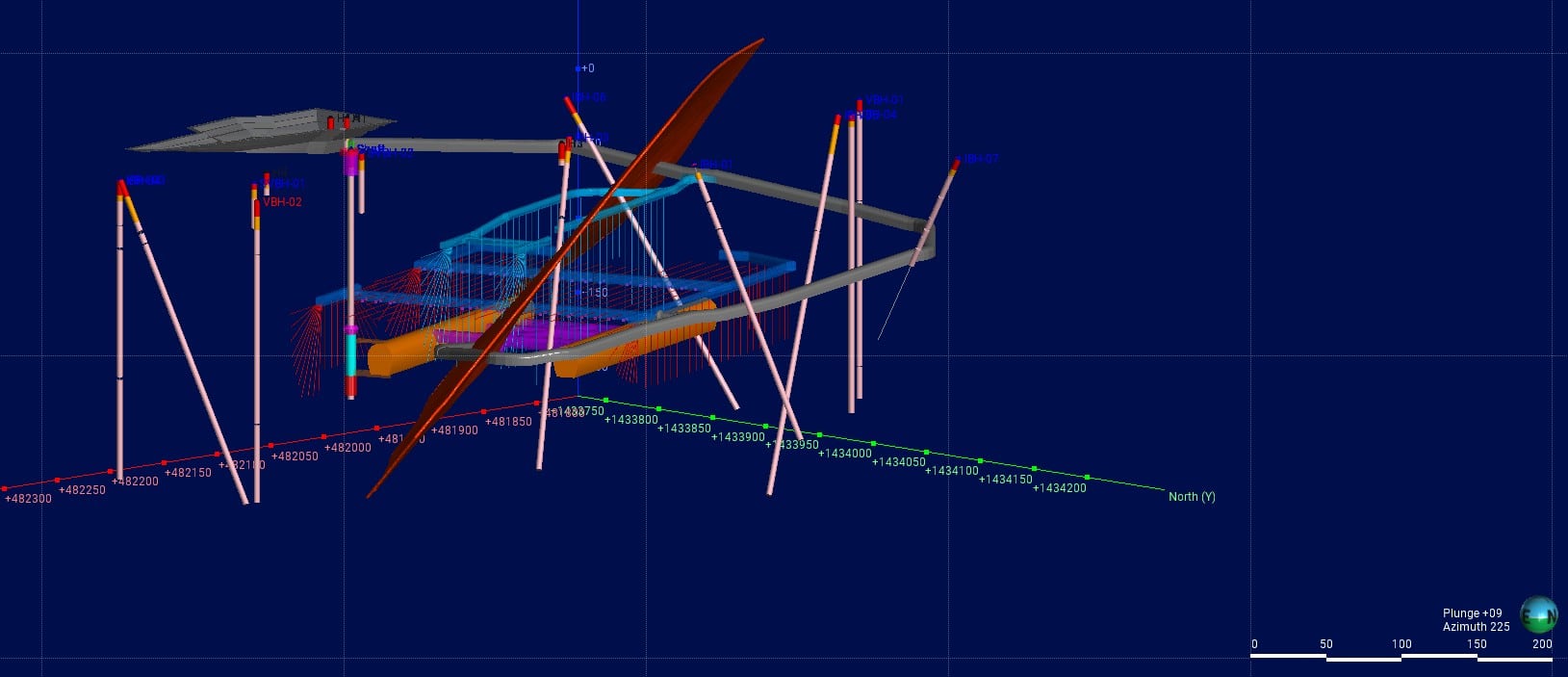

“We have imported 130 observations into our 3D cavern design and can easily input and extrapolate out any features such as Dykes or Faults. Leapfrog Works enables us to accurately represent the geology and get an advanced understanding of the underground ahead of each phase to help de-risk our project from delays in cost and time,” says Mishra.

Projection of features from investigation holes (Image: EIL)

Seequent’s GeoStudio 2D SEEP/W groundwater flow and pore water pressures analysis software has offered Mishra and the team valuable insights on groundwater flow into the cavern.

LPG stored underground is contained with the principle of hydraulic containment, with the cavern’s depth allowing surrounding groundwater to flow through rock fissures towards it and preventing LPG from escaping.

“Using the connected workflow of Leapfrog Works with GeoStudio helped us determine the fracture flow values to enhance the safety of the storage facility. While the cloud-based team collaboration platform Seequent Central enabled us to quickly and easily share and communicate any updates and risks with our stakeholders,” says Mishra.

Modelling of adverse geological features (image: EIL)

Setting the design standard across major civil projects

Introducing Seequent’s innovative subsurface technology across major civil infrastructure projects is helping the EIL team reinforce the Government of India’s geological regulations and meet international standards.

EIL follows the Bureau of Indian Standards (BIS) the Oil Industry Safety Directorate (OISD) and the International Organization for Standardization (ISO).

“We work on large, complex projects in geographically and geologically challenging locations that require detailed subsurface design. Leapfrog Work’s dynamic, 3D geological modelling is definitely helping us achieve the level of design detail required,” says Pal.

“We’re impressed with Seequent’s high level of technical support and interactive training sessions. Creating these amazing 3D models, guided by expert engineers and hydrogeologists with real-world experience on projects such as ours, is incredibly helpful. The time and effort the Seequent team put in to help build our skills and knowledge has made all the difference,” says Pal.

Seequent software is being used on other major civil projects across India, including The Pinnapuram Integrated Renewable Energy Project (IREP) – a combined solar, wind and pumped storage hydroelectric power project being developed in Andhra Pradesh