Cameco Corporation is the world’s largest publicly traded uranium company, providing about 17% of the world’s production from mines in Canada, the US and Kazakhstan. For the last few years Cameco Exploration has pursued a goal of digitising their business. The last component, the centralising and standardising of all active exploration projects, research, generative 3D data, has been achieved by using model management platform Seequent Central. The new process was first successfully developed and introduced into the Exploration Department and has now be rolled out to the rest of the organisation

Currently we find Central the most useful during the drilling season when we develop drillhole targeting. We all follow the same model and we know where the data has come from. A key benefit therefore has been increased confidence in our modelling process and in making the modelling outcome repeatable and easier to understand.

SARAH WANG, INFORMATION MANAGER, CAMECO’S EXPLORATION

Cameco Exploration’s Director of Information, Mike McClelland says, “We operate in a very competitive market and our people have to find ways to be innovative to continue to build competitive advantage. The goal to digitize has been key and Central has allowed us to achieve centralisation of 3D geoscience data. Central satisfied everything we wanted it to do. Everyone in the Exploration team is now using a common process as far as planning drill holes and managing and visualising geological models.”

Central Product Manager, Peter Joynt says, “Cameco is an innovative and forward looking company keen to challenge the status quo. They recognise that data is a critical asset and want to get the most out of it through technology. It quickly became apparent that they were not only committed to Central but they also wanted to actively contribute to its development so that the advancement of the technology will be beneficial for the industry.

“Through their hard work and dedication, the Exploration team have improved efficiency and self-service and have helped drive through innovation. I would say that Cameco are leading the mining industry in terms of how they manage data.”

The Situation

Single source of truth

Central is the only geological model management platform currently available. It provides a single source of truth for 3D models and delivers better management for everyone involved in a modelling project from the geologist, the manager, the consultants and the senior executives who rely on the models for decision making.

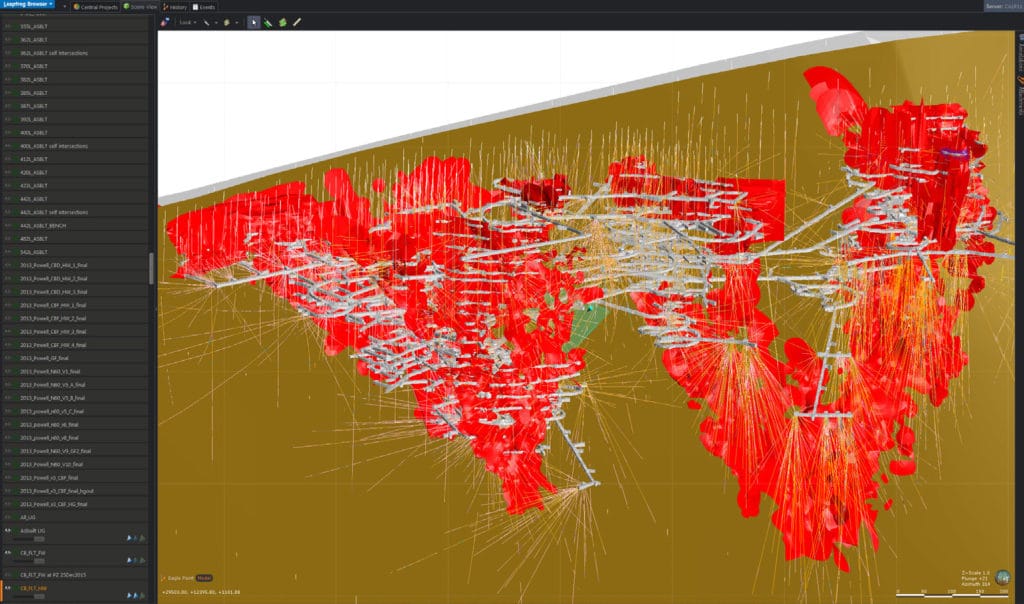

Sarah Wang, Cameco’s Exploration Information Manager, explains why implementation of Central became essential, “Such a huge amount of effort and money goes into our geological models that we need to manage them as efficiently as possible. Before Central multiple versions of models could be scattered across network folders and on different computers. With no efficient way to identify and share the most up-to-date version users could be working on outdated models. Models also weren’t standardised, making it difficult to navigate a large number of objects.”

Ease of adoption

Transforming the department’s approach to modelling started with standardising the modelling process and getting all digital data in order. Working quickly and collaboratively the Exploration Central pilot project team worked through processes to streamline and standardise, this included developing templates for data input, standardising domain codes and colour maps.

“This consistency is subtle but actually really important,” says Peter Joynt. “Cameco have exploration projects all over the Saskatchewan basin and the geology doesn’t change just because you’re in a different location, you’re still seeing the same sandstone but in a different area, so having coloring and naming consistency means models are far easier to work with. Whoever picks up the project, from a junior geologist through to the VP is already familiar with it and they can quickly interpret and work with it. This has the added benefit of increasing collaboration and improving decision making.”

Achieving standardisation of input data, publishing and sharing meant that new exploration projects could be easily added to Central. Cameco Exploration also established a project structure to help promote the standardised outputs. Peter adds, “The thing that really stood out to me from an early stage was that everyone was onboard. Cameco are open to change and committed to it.”

Cameco helped smooth implementation by recruiting advocates across the department to help explain and demonstrate proof of concept peer to peer. The software implementation itself went well and Cameco were able to quickly prove that functionality was there as required. Cameco then ran with the new best-practice approach, introducing it into their Cigar Lake Mine, the largest high grade uranium deposit in the world. The new process included introducing much more regular updates to their geological modelling, allowing users to confidently and efficiently access the most recent geological models, and giving more people access to information.

It’s more than just the data that’s residing in the one place, it’s about diligence. Rather than going through three layers of people to understand what one person’s doing it’s the click of a button.”

MIKE MCCLELLAND, DIRECTOR OF INFORMATION, CAMECO EXPLORATION’S

The Benefits

Cliff Revering, Chief Geologist at Cigar Lake Mine comments: “A significant challenge when working with numerous stakeholders is the ability to effectively and efficiently disseminate information, and maintain version control on that information. Central provides a unique platform that allows stakeholders from across an organization to access and share the latest information and geological interpretation, enhancing the overall business decision making process.”

Once operational the new process delivered on these benefits, although with some surprises, including the wider uptake in the use of 3D. The process also provided a valuable ‘lessons learned’ source of information for other operations as they go through implementation themselves.

Confidence in live implicit modelling

Central is enabling live implicit modelling with direct connection to acQuire housed targeting and drill data, as well as drill hole planning and management.

Sarah Wang: “Currently we find Central the most useful during the drilling season when we develop drillhole targeting. We all follow the same model and we know where the data has come from. A key benefit therefore has been increased confidence in our modelling process and in making the modelling outcome repeatable and easier to understand.”

Strong team collaboration

Central is bridging the team gap and helping the Operations and Geoscience teams communicate more effectively.

Sarah Wang: “Now they come up with optimum drill targets together, previously the teams worked by passing on a PDF, they’re actively collaborating.”

Visible decision making

Using Central managers can look back visually over model development and drill down to see how decisions have been reached, delivering increased transparency. This 4D approach to modelling, where time and change can be visualised and understood, adds even more insight into the decision-making process.

For Mike McClelland and his fellow directors this is a key aspect: “It’s more than just the data that’s residing in the one place, it’s about diligence. Rather than going through three layers of people to understand what one person’s doing it’s the click of a button.”

Making 3D more widely accessible

Introducing Central has opened up the use of 3D from the conventional ‘specialist’ role to everyone in the department. The 3D world allows data to be analysed from every angle, transforming it into a landscape that can be explored with the human eye.

Mike McClelland: “We’re just in our infancy in terms of getting Central out to all stakeholders but certainly even at director level there is an uptake in wanting to get into the 3D world. We have created an environment where people are excited, it’s feeding their curiosity and we have their attention. People want to get on board.”

The Future

Central will now be introduced to other operating mines so that all departments can share models, learn and collaborate. Going forward the new system will improve consistency with the way Cameco undertake their day to day modelling on a company-wide scale. Users include mine sites, mineral resources management, and exploration, which could foreseeably include greater than 100 employees.

Sarah Wang will further develop and promote best practices and advance the use of Central at Cameco. “I think it is our role as the custodians of data to realise technologies that will guide our business and unify our employees, Central is a key component.”

Mike McClelland says, “Cameco pushes the edge of technology and exploration in the depth and size of targets we pursue. We are drilling upwards of 1,000 meters to try to hit something that may be just 30 meters wide. Sustainability and repeatability is integral to how we operate day-to-day and it helps us manage risk and drive innovation. I’m very pleased with how our relationship is maturing with ARANZ Geo and how we are able to get involved in shaping Central.”

Comments from Central’s Product Manager, Peter Joynt, “Cameco is one of our early success stories as they are already achieving great outcomes at a relatively early stage. They’re building a rich auditable history for their projects and they will be able to leverage the latest product developments going forward. This case study demonstrates how Central can transform business practices and take modelling to a whole new level. Central has also openedup 3D to the wider organisation and in doing so has accelerated understanding and improved decision making. In such an important sector as Uranium it’s essential that efficiency is so doggedly pursued and we’re proud that Central is contributing to our client’s becoming even better custodians.”