While Leapfrog Works is used in a number of major engineering projects, it also has a role to play in smaller scale schemes – especially those trying to avoid the expense, complexity and skill-set demands of traditional modelling solutions.

This year in Hamburg, the pressing need for more living space prompted developers to propose housing plans for a former school and a disused landfill site next to it. Demolishing the buildings and reutilising the land could create more than 200 flats. However, the potential contamination called for a detailed environmental investigation to assess the subsoil, and make recommendations for safe foundations (including settlement and ground seepage calculations) drainage systems, excavation pit construction and more.

The Lieberman Engineering Company, contracted to carry out the survey, also saw another opportunity within the commission – a chance to advance their own digitisation in preparation for Industry 4.0 (a future, high-tech vision of the German government).

They seized the moment to diverge from a traditional CAD-based modelling approach – and its high-level skill demands – and connect their teams with the easier to understand functionality of Leapfrog. The resulting 3D models would help a multitude of stakeholders understand the issues more easily and drive the project forwards. But the experiment would also invest Lieberman’s own people with a set of valuable, futureproofed abilities and experience.

The Challenge

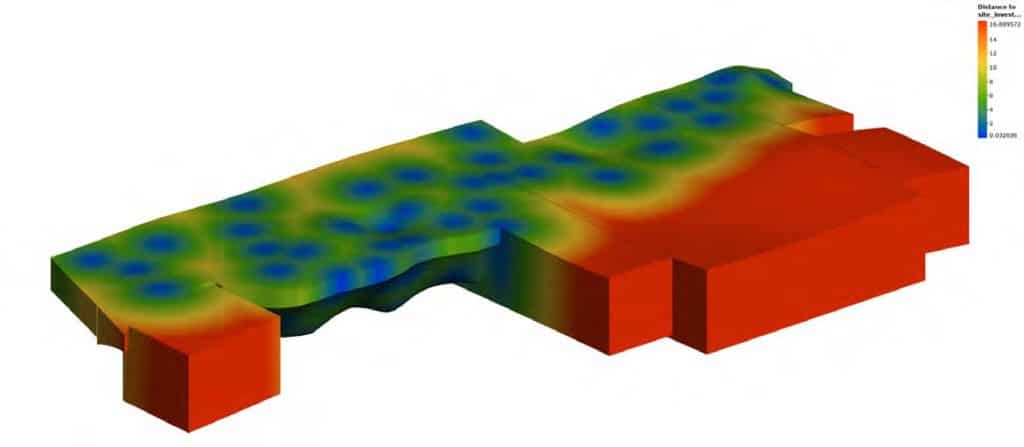

To minimise remediation costs the investigation needed to establish the exact volumes of overburden and different contamination levels to arrive at a safe and economic disposal concept. This clarification would determine which areas and volumes were to be excavated for the new buildings and which areas would need to be disposed of.

However, most BIM-capable products used for such geological and geotechnical applications require extensive CAD knowledge. This can make them prohibitively expensive for small or even mid-sized projects as this one. Leapfrog Works was able to offer Lieberman more approachable and

affordable digitisation of data, yet still in accordance with the requirements of the BIM working method.

“Due to Leapfrog’s intuitive functionality, geologists or geotechnical engineers are able to work on models themselves, rather than employing a CAD specialist as we’ve had to with other modelling solutions,” said Tobias Querfurth M.Sc., Geological Engineer for Lieberman. “This means we can use Leapfrog for even small projects and can integrate it into a consistent digitised workflow that can become standard for all of our geotechnical and geological projects.”

Getting the attention of stakeholders early on

Such projects also attract a further challenge around communication, explains Querfurth. It’s one that may be familiar to many. “We often see that our geotechnical results, which are important in the early stages of a project, only receive full attention in late planning phases. If further investigations or changes to plans have to be undertaken in these phases, costly project delays can quickly occur.”

Leapfrog Works took on the role of a central communication platform for stakeholders at this early phase, enabling smooth and transparent communication. As Leapfrog models are also built directly from data, they could be readily updated as new project information was added, supporting better decision making throughout the project’s lifecycle

The Outcome

“To test the effectiveness of the Leapfrog solution, and its digitisation potential going forward, Lieberman also ran their existing 2D method in parallel to form an early appraisal. Leapfrog Work’s 3D approach was not only twice as fast as 2D, but it gave us much more clarity from the start of the project,” said Tobias Querfurth. “It’s also easier to share with non-technical stakeholders, as we all tend to imagine in 3D.”

- Performing a mass calculation using the solids from the 3D model enabled Lieberman to significantly reduce the expected disposal costs.

- The ability to rapidly update data and models meant that areas requiring deeper investigation could be identified quickly, speeding the project along. Information gaps could also be spotted earlier, further reducing costs.

- With the disposal concept completed, it should now be easy to update it with further refinements around soil categorizations and additional data as it comes in, for example on the vast number of chemical substances present – lead, copper, polycarbonate and more.

The Future

And as for the learning experience? A success, confirms Tobias Querfurth. “In fact it is our hope that this project will create a digital standard for Lieberman Engineering, and will lead us to favour digital processes going forward. Visualisation of the abstract data provided us with a better project overview. Sharing visualisations early in the project reduced the risk of time-consuming and costly supplements that could be needed later on. And as we’re easily able to import and visualise new data, decisions could be made faster.”